Area: Engineering & Manufacturing

Type: Dencrete

15,000 m2 of Dencrete HF

withstands high heat and heavy trucks

The Challenge

"The floor must be able to withstand the heat from the large stoves"

The Spanish company Torrecid produces, among other things, clinker, tiles and glass, which takes place in large smelting ceramic melting ovens. The high temperatures and the radiant heat from the kilns had caused the old concrete floors to crack and crumble, and this sometimes cost both whole and half truckloads of fragile ceramic goods.

The Project

"Can we avoid moving the furnaces?"

The old concrete floors had to be renovated, but since the kilns were originally mounted on top of the concrete, it was not realistic, in terms of time, to break up the floors, move the kilns temporarily and then cast new concrete. In addition, the new concrete would crack in the heat.

Instead, Torrecid, in collaboration with Dencoat, chose the heat-resistant Dencrete HF in the casting hall, which could be laid in a few days after the concrete had been renovated around the furnaces. Torrecid could thus avoid a prolonged shutdown of production.

The solution

"Our Dencrete HF mortar can withstand the heat and protects the underlying concrete"

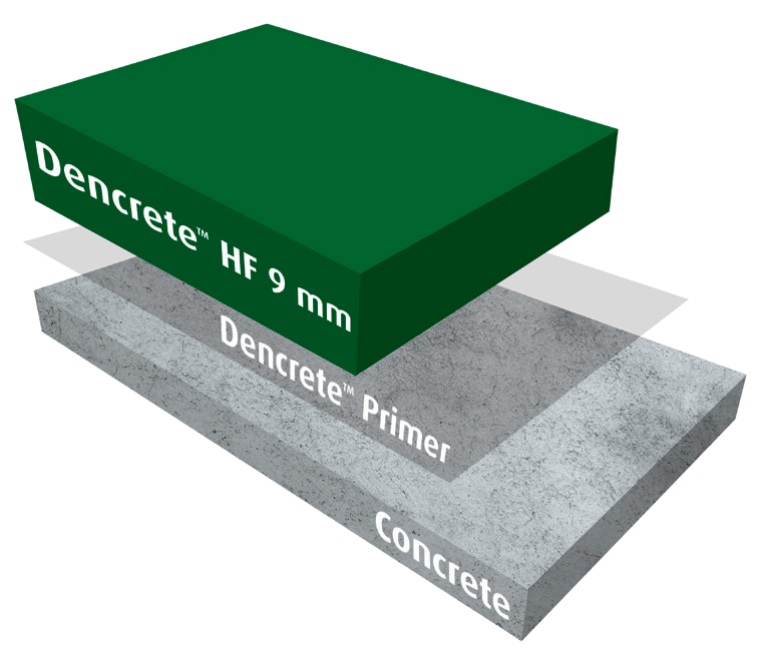

Following the concrete repair, 5,000 m2 of Dencrete HF Mortar, a pu-based mortar system with cement-based filler, was laid, which is the most heat-resistant system on the market for self-levelling floors.

Dencrete Mortar can withstand up to 130 degrees C and is laid in one efficient operation, regardless of layer thickness. Another advantage is that Dencrete protects the underlying concrete from the heat.

In less heat-critical areas, 10,000 m2 of Dencrete MD was laid. Both floor types are seamless and can withstand aggressive chemicals, high heat and heavy trucks.

The customer

Torrecid, headquartered in Alcora Castellón, is a major Spanish manufacturer of tiles, tiles and glass, as well as various ceramic coatings, glazes and pigments for other manufacturers worldwide.

Torrecid states that Dencoat's work to renovate the old degraded concrete floor and lay a new floor was carried out within the agreed timeframes and with great flexibility, ensuring minimal downtime of production.

The installer

The Spanish flooring company Mortec's work team managed to operate within a very tight schedule, with the work being divided into 3 phases that required the respective furnaces to be shut down briefly. Mortec focuses on excellence in each project and establishes relationships of trust and professionalism with its customers and suppliers.

Dencoat India

Dencoat India