Area: Engineering & Manufacturing

Type: Dencryl

The Rolls Royce of floors

also is the Floor of Rolls Royce!

When Rolls Royce Marine needed to renovated their facilities, they called upon Dencoat.

The Project

In one of the most scenic parts of the norwegian landscape, Rolls Royce Marine produces Heavy Duty Equipment for the oil and marine industry.

Like the famous cars of same name, proud craftsmanship combined with the latest technology is put into the production of special submarines and gigantic ship propellas.The requirements from the production explains why this is not your average production floor. Due to the extremely heavy loads passed to the floor, the engineers had to design a very special floor build up. Special heavy load steel bars was installed every 1 meter through the production area to absorb the weight ot the special submarines produced here, each exessing a weight of more than 20 tons per unit, covering only a space of 4 sqm. Naturally a tough challenge for any floor construction, so Dencoat therefore decided together with the engineering office at site to install Dencryl Industry in between the steel bars so the massive load still is supported. Because of the high flexability and durabillity of the Dencryl Industry system, no cracking or spalling occurs between the steel bars and the Dencryl Industry system during production. Aftermarked Workshop Manager Geir Sunddal explains:" Our customers require 24 hour service from our side. When a bulk carrier or a passenger ship looses or damage its propella, time is money. We must be able to respond immidiately, and hence to this we need production facilities that can live up to this. The floor is an essential part of our capability to produce and therefore we can only accept the absolute best the marked can offer. We have now installed more than 3.000 m2 of Dencryl Industry, and so far we have been absolutely satisfied with the quality of the system.We have had some minor repairworks made, and thank to the very fast curing of the Dencryl system, this has no influence on our production schedule".

Our Customer

Rolls Royce Marine, the former Ulstein Yard, is located on the island Ulsteinvik, close to Aalesund, Norway. Strategically placed with direct acces to the North Sea, the yard produces equipment for the oil and marine industry. More than 2.000 people works on the site, which makes it the largest employer by far in the region.

Our installer

KA Gulve has 25 years of experience with various types of flooring of quality flooring and operates throughout Denmark.

-My background is that I have laid floors all over the world and participated in several foreign projects in Russia, Hong Kong and Dubai, among others. The preparatory work is the most important thing, both to ensure a level floor, but especially to create a solid foundation for adhesion. The most important thing for us is that the customer is satisfied. It also means that we work carefully and meticulously review the finished work. If we see the slightest mistake, we correct it. In fact, we have never been out to change anything, Kim Andersen concludes.

We know the solutions…

With many years of experience in the manufacture and application of resin based surface materials, Dencoat is renowned as one of the leading experts in this field.

Our knowledge will provide tailor made solutions to meet specific needs. With our latest updates in technology based on epoxy, polyurethane and MMA resins, we can guarantee that your result will be prescribed to the ultimate of what can be achieved

Project Facts

Customer

Rolls Royce Marine

Location

Ulstein, Norway

Year

2005

Project size

3,000 m2

DenCoat™ System

» Dencryl™ Industry

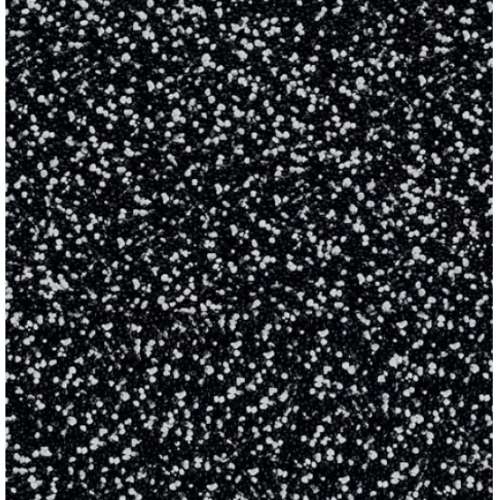

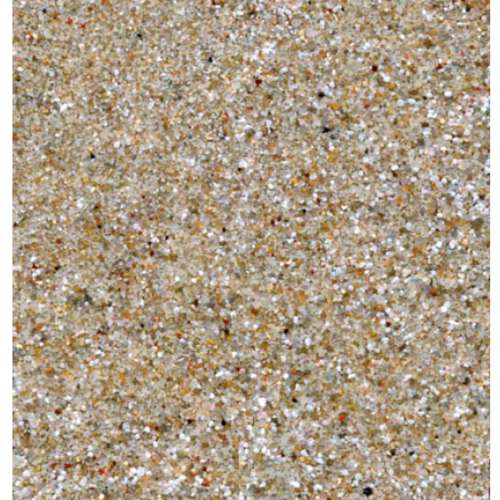

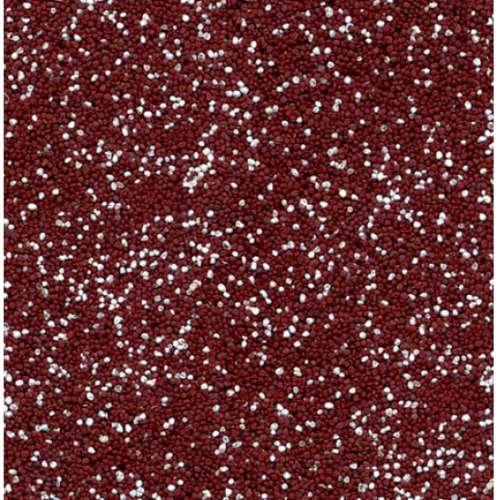

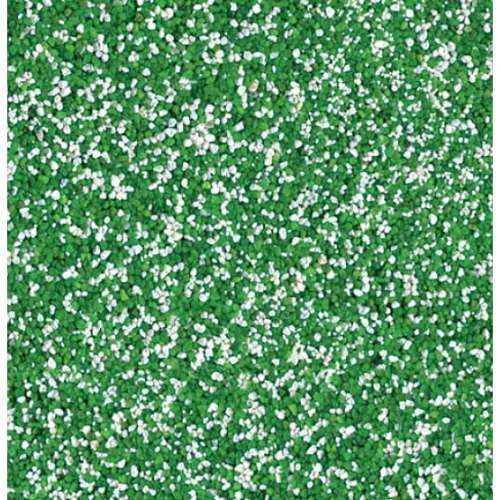

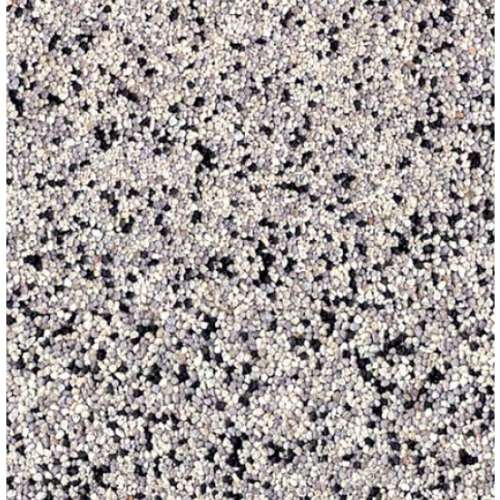

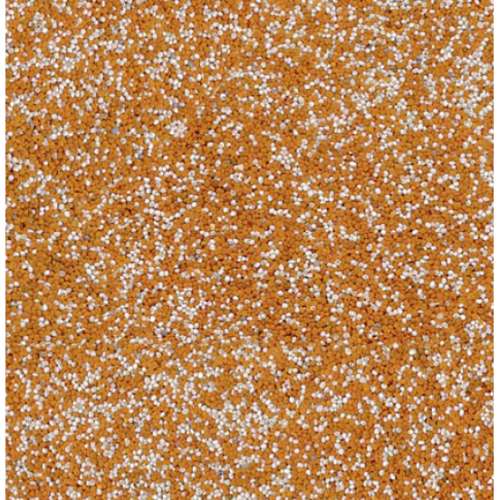

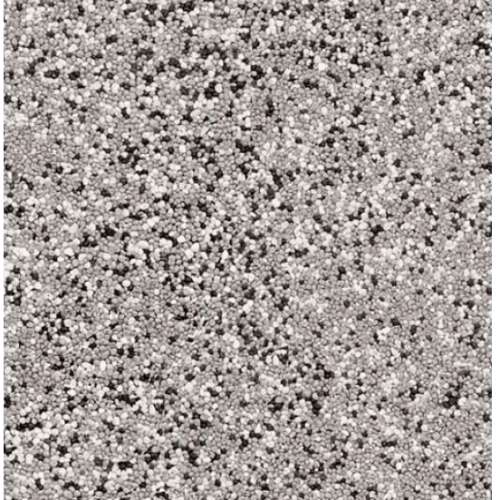

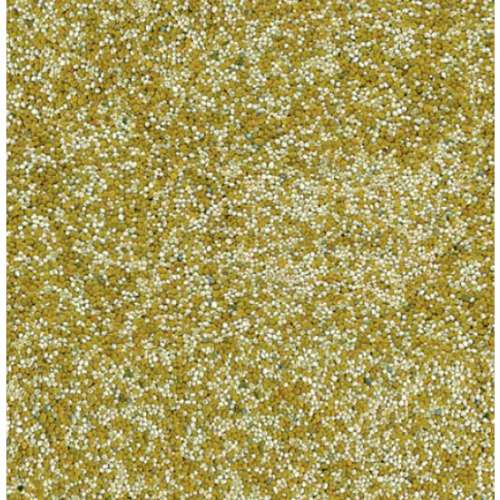

Colour

» Colour Quartz

FACTS

2005

2005

3.000 m2

3.000 m2

Color Quartz DC61

Color Quartz DC61

Dencryl Industry

Dencryl Industry

Heavy industry

Heavy industry

Smooth

Smooth

Ulstein, Norway

Ulstein, Norway

BENEFITS

Aestetically pleasing, silkmat surface

Aestetically pleasing, silkmat surface

Attractive Appearance

Attractive Appearance

Fast Installation

Fast Installation

High Abrasion Resistance

High Abrasion Resistance

High Impact Resistance

High Impact Resistance

Non Slip Seamless & Flexible Finish

Non Slip Seamless & Flexible Finish

Very Good Chemical Resistance

Very Good Chemical Resistance

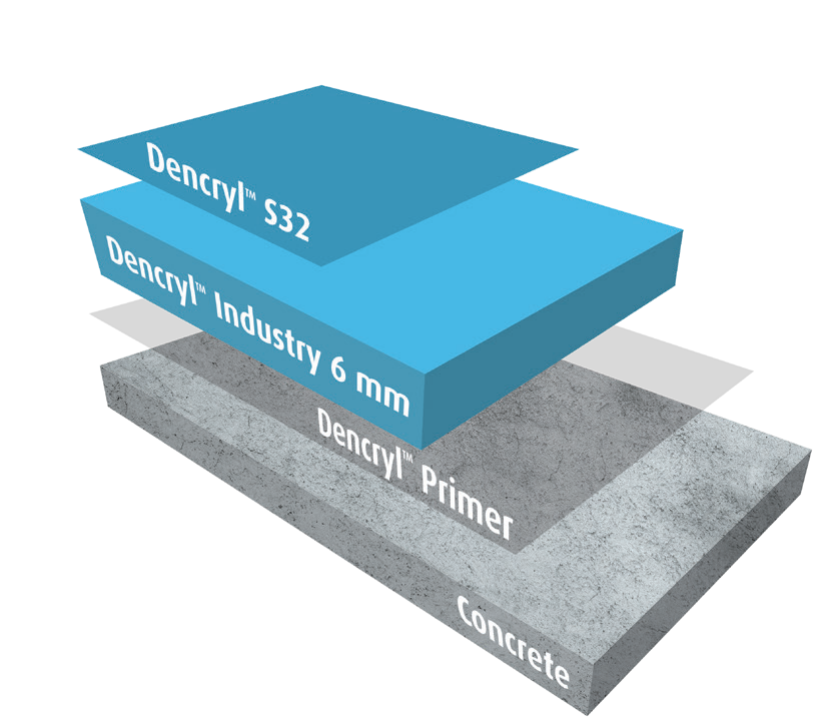

SYSTEM BUILD UP

Dencryl™ Industry

DC 10

DC 20

DC 30

DC 41

DC 50

DC 61

DC 70

DC 80